OUR PORTFOLIO

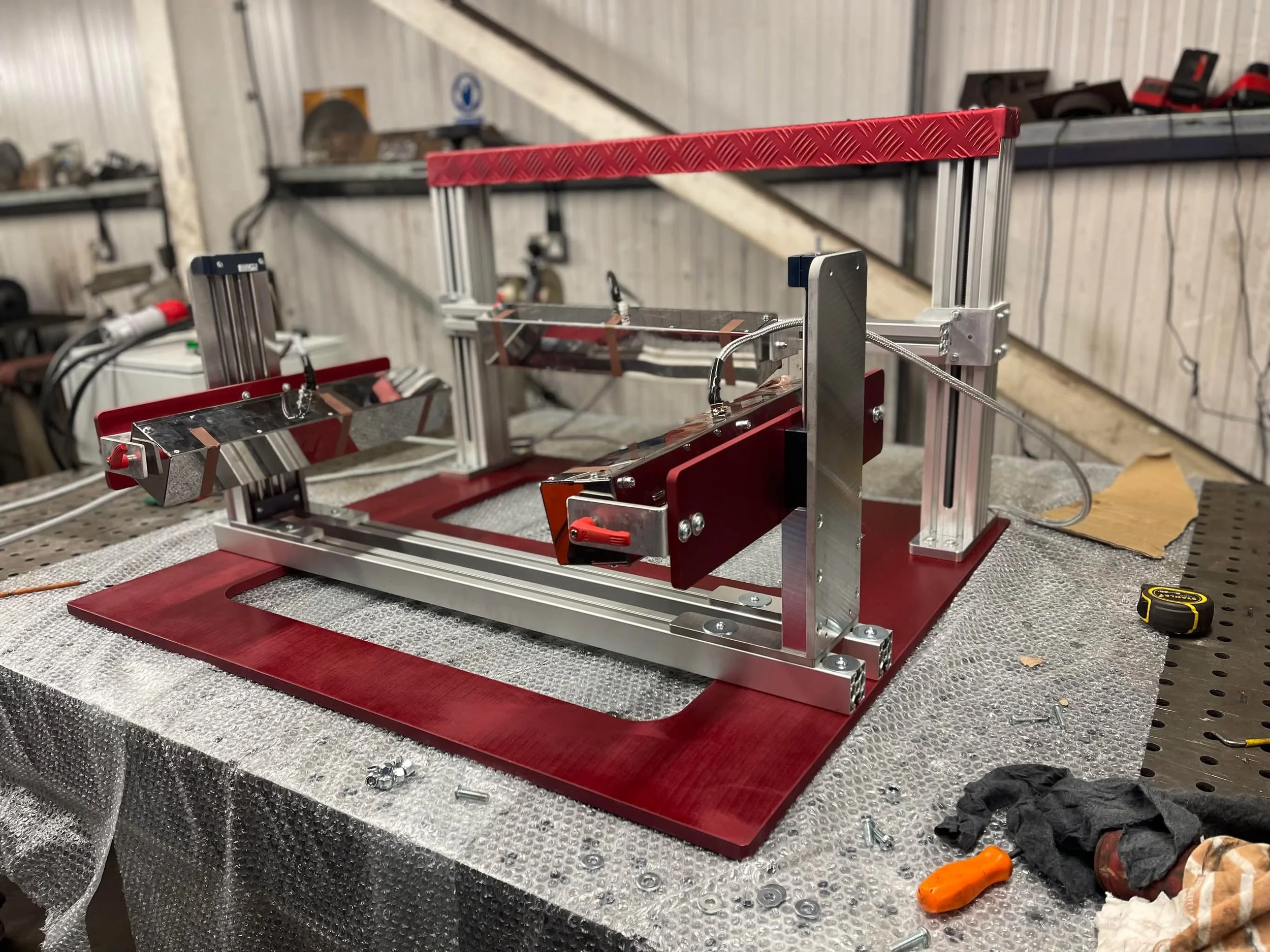

Industrial Three way Infrared Heater

Three-way infrared heating system engineered to deliver highly efficient and uniform thermal conditioning for PVC sheet extrusion processes. The design incorporates three independently controlled IR heating zones arranged to maximize surface coverage, stabilize surface temperatures, and ensure consistent sheet surface and bow quality.

Constructed on a rigid, modular aluminum framework, the system integrates infrared emitters to optimize heat distribution and energy utilization. Adjustable positioning mechanisms allow fine tuning of heat angles and distances, enabling operators to tailor thermal profiles for specific material formulations and extrusion speeds. Developed for demanding industrial environments like extrusion process lines.

DISINFECTANT DISPENSER

This patented medical iodine applicator was conceived, designed, and developed by our team from initial concept through to fully mass-produced product. Created as a sustainable re-engineering of a common single-use applicator that typically ends up in land waste, the new design increases material recyclability to 75% while maintaining full compliance with medical regulations and performance standards. Through detailed research of existing products, iterative design development, and rigorous engineering for manufacturability, the final solution delivers improved usability, reduced environmental impact, and seamless integration into clinical workflows. I am listed as the named designer on the patent, reflecting my end-to-end role in the innovation and development process.

SipGrip

SipGrip is a bespoke ergonomic handle designed to add secure, comfortable grip functionality to metal water bottles that lack built-in handles. Engineered for universal compatibility, SipGrip installs quickly without tools and locks firmly in place for safe everyday use. Its contoured geometry provides a natural, stable hand position, making it ideal for children, gym users, commuters, or anyone who wants a more confident hold on their bottle. Lightweight, durable, and moulded for all-day comfort, SipGrip enhances usability while maintaining the bottle’s original aesthetics—turning a simple bottle into a more practical, user-friendly hydration solution.

MEDISENTRY (RSA)

This RSA briefed project focused on the end-to-end development of a functional product solution, from initial research and concept generation through to refined prototyping and final evaluation. The process began with user and market analysis to define the core problem and design opportunities, followed by iterative sketching, CAD development, and rapid prototyping to validate usability and performance. The final outcome demonstrates a balance of technical feasibility, manufacturing awareness, and thoughtful design intent—reflecting a rigorous, practical approach to product development.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!